About inspection standards

All products sold in our store are inspected at the time of production.

All of Doso Towada Kiln's pottery is made by hand, so each pottery has its own individuality.

The characteristics of our ceramics and our inspection standards are listed below, so please understand and acknowledge them before purchasing.

Basic policy

Items that occur during production even though they could be prevented are considered defective.

If it is a force majeure event that occurred during the production process or inside the kiln, and if it is determined that there is no effect on normal use, the pottery is considered to be non-defective.

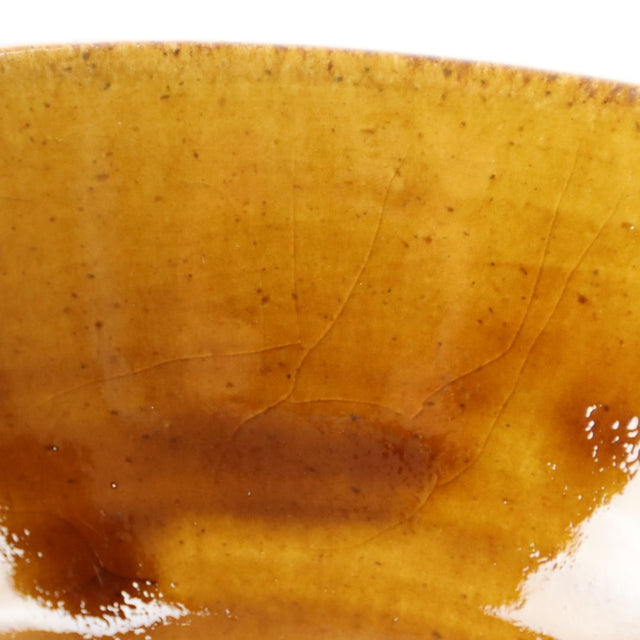

・Penetration

It refers to the fine crack patterns that occur in the glaze of ceramics. This pattern is created by the difference in the degree of shrinkage between the clay and the glaze when it is cooled after firing.

Since it is not a crack like a crack, liquids etc. will not penetrate into the clay. Please enjoy it as one of the expressions of the vessel.

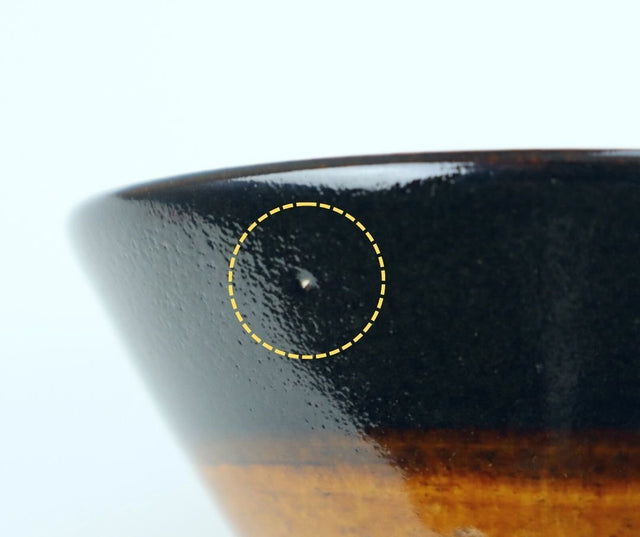

·Pinhole

Air and organic matter left in the base material during bisque firing may remain as small holes during firing. At our store, we inspect the pieces when they arrive, but if there are small pinholes that do not appear to be a problem in use, we will treat them as being in good condition.

・Iron powder

When the pottery is fired, the iron contained in the clay may oxidize and appear as black dots on the surface.

Basically, the product is considered to be in good condition, but if iron powder is present over a large area, it is considered defective.

・Uneven glaze

The glaze is applied by hand to each vessel. Therefore, the thickness may not be uniform. The unevenness of the glaze has long been considered an object of appreciation as a ``scenery of the vessel'', so we generally treat it as a good item.

・Painting fading/bleeding

Since the finish of the painting varies depending on the thickness of the paint, the temperature at the time of firing, the climate, etc., we generally treat it as a good product, but if it is due to negligence, we will treat it as defective.

・Distortion of molding

Most of the pottery is made using a potter's wheel, hand rolling, or molding. Since each piece is hand-made using traditional methods, each piece has its own unique finish, such as not being perfectly symmetrical or having different heights.

Since we consider this to be an expression of the pottery, we treat any slight distortion as a good item, but we treat vessels with large distortions as defective.

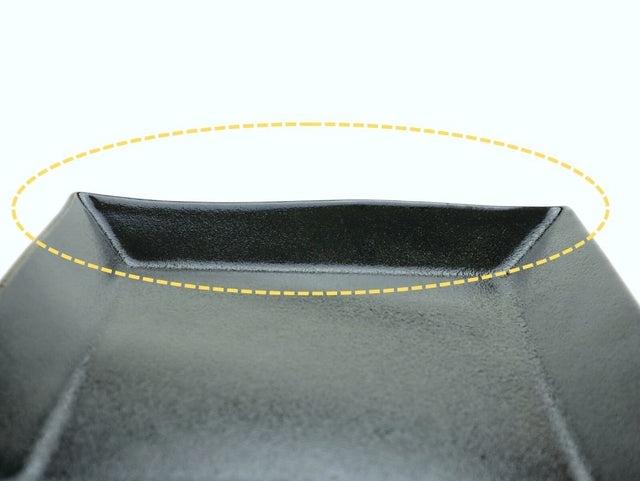

・Ruttle on high ground

As well as molding distortion, there are individual differences in the height and thickness of the platform. Items that have a large amount of wobbling during inspection are judged to be defective, but items that are slightly rattled are judged to be good.

We use a whetstone to finish the product during inspection, but if you are concerned about wobbling, you can sharpen the base with a whetstone or sandpaper to stabilize the vessel.

・Cracks/chips

If the product has cracks or chips that may cause quality problems during use, we will treat the product as defective upon arrival.

No two pieces of pottery are the same. If you would like to check the actual product before purchasing, please contact us. We will explain as much as possible, including actual images.

Penetration

Penetration Pinhole

Pinhole iron powder

iron powder uneven glaze

uneven glaze Fading/smearing of glaze

Fading/smearing of glaze Penetration of bran glaze that has been used for many years (can also be prevented by sealing)

Penetration of bran glaze that has been used for many years (can also be prevented by sealing) Some distortion due to the condition of the clay

Some distortion due to the condition of the clay